|

APIs, concepts, guides, and more

|

|

APIs, concepts, guides, and more

|

Manage motion halts due to position errors, caused by discrepancies between actual and commanded positions due to configuration, mechanical, software, tuning, or electrical issues, adjustable via controller or drive settings.

A position error fault could be thrown by either the Servo drive or the Controller the difference between the actual position of a motor and the commanded position exceeds the limit threshold or trigger value. There are many potential causes for a difference between these values:

| Issue | Type |

|---|---|

| The Position error limit trigger threshold is set too low | configuration issue |

| The axis hits an obstruction preventing it from following the command position | mechanical issue |

| The axis is commanded to move at impossible accelerations or speeds | software issue |

| The axis has instability causing it to oscillate | tuning issue |

| Motor is could be wired incorrectly | electrical issue |

A position error can be raised by the controller or drive firmware. Usually one of them would have a tighter limit so that would be the one that always triggers.

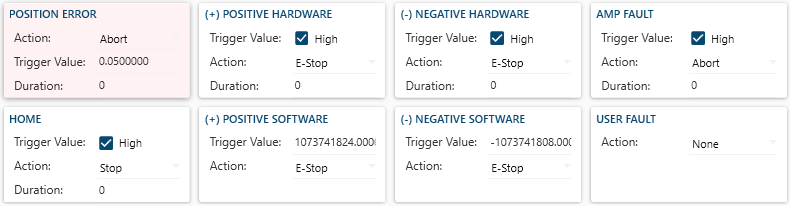

If the controller throws the fault it shows up in RapidSetup as a position error limit and the Position Error box will be red on the Limits and Actions Tab:

If the servo drive throws the fault, then it will show up in RapidSetup as an Amp fault (439 following error) and the AMP FAULT box in the limits and Actions tab will be red.

The most common cause of position error is a too tightly configured position error in the Axis. You can loosen the tolerance using: ErrorLimitTriggerValueSet().